Post by Beans on Feb 4, 2013 19:04:07 GMT -5

Q:What is valve to valve clearance (V2V) and why do I need to check it?

Well to start, valve to valve clearance is basically what it sounds like; that is, the closest distance from the intake valve and the exhaust valve. But first let's address a few points first. V2V clearance only needs to be checked on interference engines (an engine where if the timing belt snaps the valves could make contact with either the piston or another valve). Furthermore, it only needs to be checked if you are installing a high lift camshaft and should be checked AFTER degreeing your engine.

Making sure that the clearance between the intake valves and the exhaust valves is crucial, especially on a high revving engine! If there is not enough clearance, your valves will clip each other and your out an engine!

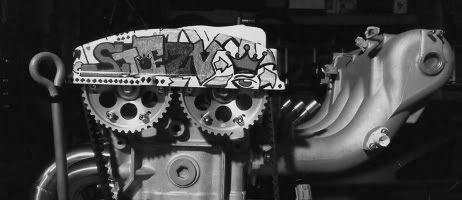

For illustrative purposes I will be using a Honda h22 engine.

What will you need?

1. Take your head and install only cylinder 1's rocker arms. DO not install number 2, 3, or 4's rocker arms as you do not want to depress those cylinders valves as they will hit the bench you are working on, and will make this process literally impossible. If you have a Honda engine with VTEC or another engine with variable valve timing make sure you lock your rocker arms and set the valve lash to 0.00". This ensures maximum lift and gives you the smallest clearance the intake and exhaust valves will come to each other. I did this by using a wooden dowel as a spacer.

2. Next, install the intake and exhaust camshaft.

3. Rotate the intake and exhaust cam to TDC and install the timing belt using the vice grips. Make sure that both cams are exactly at TDC as this will give you the true clearance between valves!

Well to start, valve to valve clearance is basically what it sounds like; that is, the closest distance from the intake valve and the exhaust valve. But first let's address a few points first. V2V clearance only needs to be checked on interference engines (an engine where if the timing belt snaps the valves could make contact with either the piston or another valve). Furthermore, it only needs to be checked if you are installing a high lift camshaft and should be checked AFTER degreeing your engine.

Making sure that the clearance between the intake valves and the exhaust valves is crucial, especially on a high revving engine! If there is not enough clearance, your valves will clip each other and your out an engine!

For illustrative purposes I will be using a Honda h22 engine.

What will you need?

- A timing belt. Make sure that you will not be using this timing belt in the future as this process will destroy it. I suggest buying the cheapest timing belt you can find off e-bay or going to a junk yard.

- Your engine head with cams.

- Vice grips

- Feeler gauge

1. Take your head and install only cylinder 1's rocker arms. DO not install number 2, 3, or 4's rocker arms as you do not want to depress those cylinders valves as they will hit the bench you are working on, and will make this process literally impossible. If you have a Honda engine with VTEC or another engine with variable valve timing make sure you lock your rocker arms and set the valve lash to 0.00". This ensures maximum lift and gives you the smallest clearance the intake and exhaust valves will come to each other. I did this by using a wooden dowel as a spacer.

2. Next, install the intake and exhaust camshaft.

3. Rotate the intake and exhaust cam to TDC and install the timing belt using the vice grips. Make sure that both cams are exactly at TDC as this will give you the true clearance between valves!